Creating A Custom Barricade Jacket For Your Event

Creating A Custom Barricade Jacket For Your Event

The allure of custom barricade jackets lies not just in their functional utility but in the meticulous craftsmanship that brings these visual spectacles to life. In this exploration, we will go into detail on Creating A Custom Barricade Jacket and a step by step analysis of the manufacturing process.

Step 1: Conceptualization and Design

The journey starts with a vision for your barricade jacket and creating a design planning. Before any material is touched, our design team collaborates closely with you to understand the event’s theme, brand guidelines, and specific requirements. This collaborative process ensures that the custom barricade jackets align precisely with the client’s vision.

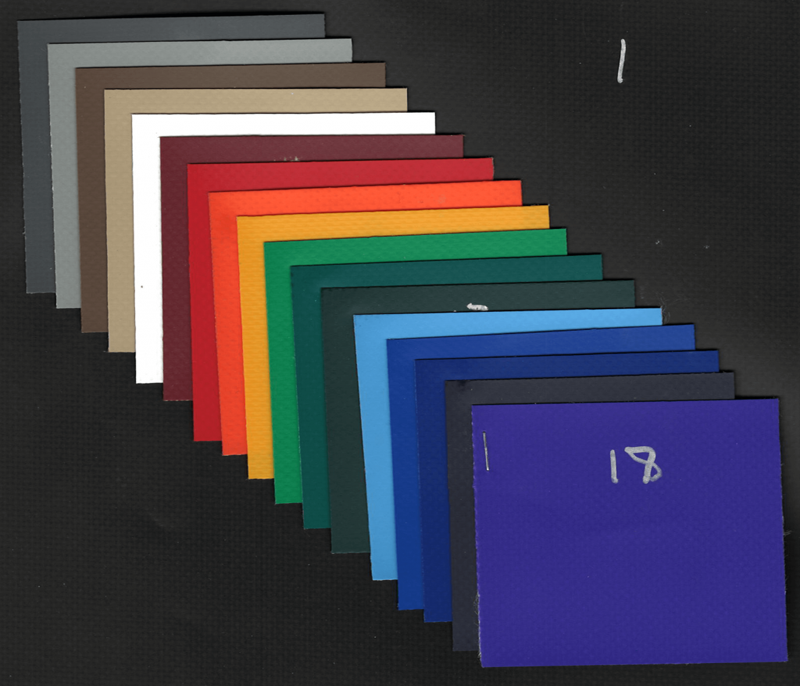

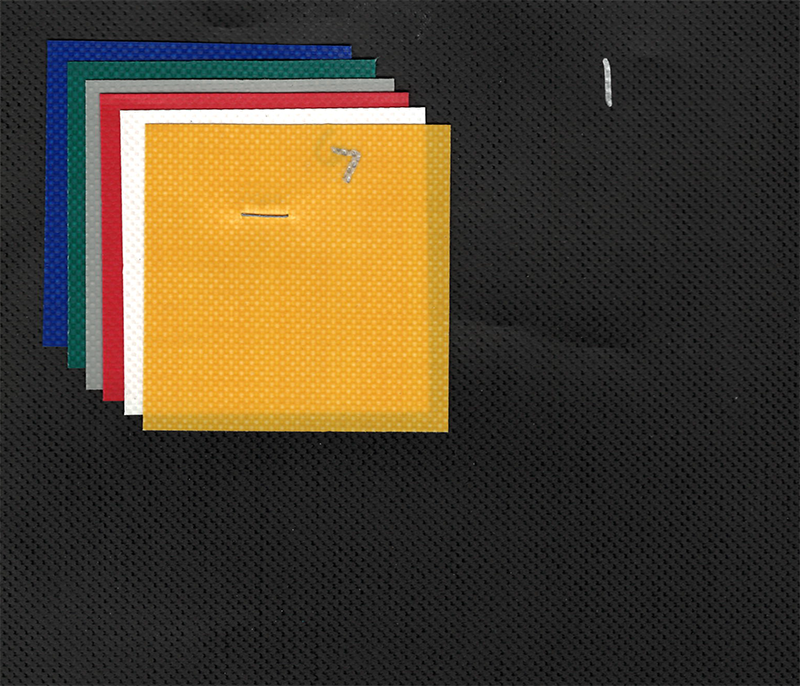

Step 2: Material Selection

Once the colors have been chosen and the design is finalized, you can now decide on a material. You can choose from an option of 18oz heavy duty vinyl material or a 10oz lighter vinyl material. This allows us to give you the option to best suit your need.

Step 3: Printing: Bringing Designs to Life

Dye Sublimation Printing:

The preferred method for printing on custom barricade jackets is dye sublimation printing. This cutting-edge technique ensures that the ink is infused directly into the fabric, resulting in vibrant, long-lasting colors. Sublimation printing offers several advantages:

Durability: The colors resist fading, ensuring the jackets maintain their visual brilliance even after prolonged exposure to sunlight and the elements.

Detail Precision: Sublimation allows for intricate details and sharp, high-resolution images, ensuring that the final product faithfully replicates the design.

Environmental Friendliness: Sublimation is an eco-friendly option, as it produces minimal waste compared to traditional printing methods.

Step 4: Precision Cutting

Once the artwork is imprinted on your selected material, the next step would be to use precision cutting to give the jacket it’s shape. Advanced cutting machinery is used to ensure each piece is accurately shaped and sized according to the specified design. This step is important as it not only makes sure every piece fits perfectly, but this also allows us to create and size or shaped jacket. Simply give us the dimensions of the barricade or product you are trying to cover and we can make you a custom sized jacket that will perfectly fit your object.

Step 5: Sewing: Crafting Cohesion

With the pieces created our industry veterans the proceed with the sewing process. Skilled seamstresses and craftsmen meticulously stitch together the cut pieces, ensuring precision and durability. Several key elements come into play during the sewing phase:

1. Panel Alignment: The individual panels, each imprinted with a segment of the overall design, are carefully aligned to create a cohesive visual narrative. The precision in panel alignment contributes to the seamless flow of the design across the entire surface of the barricade jacket.

2. Reinforcement Stitching: Critical stress points undergo reinforcement stitching to enhance the overall durability of the jacket. This includes areas where the jacket may experience tension or stress during installation or use.

3. Seam Quality: The quality of seams is of paramount importance. Double-stitching is often employed to reinforce seams, ensuring that the jacket remains intact and visually appealing even under challenging conditions.

4. Finishing Touches: The finishing touches involve meticulous inspection and quality checks. Each custom barricade jacket undergoes a thorough review to ensure that the design is faithfully replicated, the seams are secure, and the overall craftsmanship meets the highest standards.

Step 6: Quality Assurance

Before the custom barricade jackets make their way to the event venue, a rigorous quality assurance process takes place. This involves a comprehensive inspection of each jacket, checking for any imperfections, color discrepancies, or issues with stitching. Quality assurance guarantees that the final product surpasses expectations and aligns with the client’s vision.

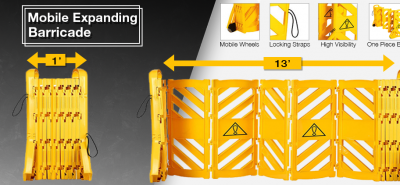

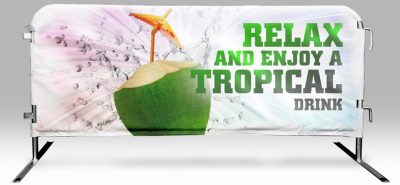

Step 7: Installation and Event Integration

The culmination of the manufacturing process is the production of a high quality and effective barricade jacket for any environment. The jackets can be strategically placed to guide crowds, enhance the visual appeal of the space, and contribute to the overall ambiance of your venue or event. The seamless integration of these crafted pieces transforms any event space into a canvas of creativity and brand expression.

Conclusion: From Concept to Creation

The manufacturing process of custom barricade jackets is a harmonious blend of creativity, precision, and craftsmanship. From the initial conceptualization and design phase to the meticulous printing, cutting, and sewing processes, each step is a testament to the dedication to quality and visual brilliance. What’s even more important is that with the help of our new partner, we can say that our barricade jackets are made entirely in the united states of America.

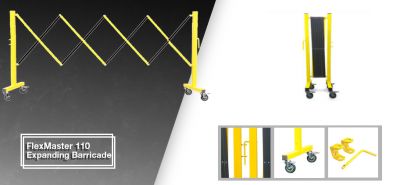

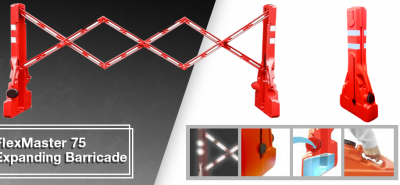

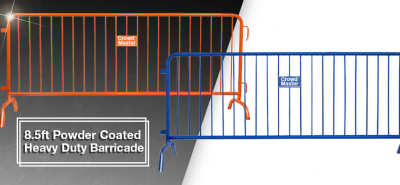

For more information about the full line of barricade products, please visit our Barricade category and explore the wide range of options available.

If you liked this post check out our most recent post Here

LEAVE A COMMENT