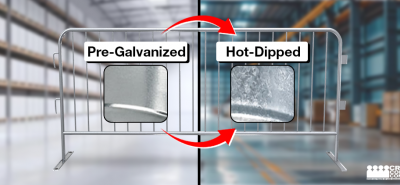

The Differences between Pre-Galvanized Barricades and Hot-Dipped Barricades

The Differences between Pre-Galvanized Barricades and Hot-Dipped Barricades

When it comes to crowd control and perimeter security, steel barricades are a popular and effective solution. They can be used in a variety of settings, from outdoor concerts and festivals to construction sites and public events. However, not all steel barricades are created in the same way. In fact, there are significant differences between pre-galvanized barricades and hot-dipped barricades. In this article, we’ll explore the differences between the two and help you determine which is the best choice for your needs.

What are Pre-Galvanized Barricades?

Pre-galvanized steel is created by taking regular steel and dipping it in a hot zinc bath before the final product is formed. This coating creates a layer of zinc that helps protect the steel from rust and other types of corrosion. Pre-galvanized steel is also known as “mill galvanized” or “pre-coated” steel. This type of steel is widely used in the construction industry, as well as in the manufacturing of many different types of products.

Pre-galvanized steel barricades are created by taking steel tubing and forming it into a barrier shape. The tubing is then pre-galvanized before it is welded together to create the final product. Pre-galvanized barricades are generally less expensive than hot-dipped barricades, which makes them a popular choice for those on a budget. They are also lighter in weight, which can be an advantage if you need to move them frequently.

What are Hot-Dipped Barricades?

Hot-dipped steel is also created by dipping regular steel in a hot zinc bath. However, the process for creating hot-dipped steel is slightly different than the process for creating pre-galvanized steel. In the hot-dipping process, the steel is cleaned and pickled before being dipped in the zinc bath. This helps to create a stronger bond between the steel and the zinc coating.

Hot-dipped barricades are created using the same process as pre-galvanized barricades, with one important difference: the tubing is hot-dipped after it is welded together to create the final product. This creates a much thicker and more durable layer of zinc coating on the steel, which provides better protection against rust and corrosion. Hot-dipped barricades are generally more expensive than pre-galvanized barricades, but they are also much more durable and long-lasting.

Advantages of Pre-Galvanized Barricades

Pre-galvanized barricades are a popular choice for a number of reasons. One of the biggest advantages of pre-galvanized barricades is their low cost. Because the zinc coating is applied before the tubing is welded together, the process is less labor-intensive than hot-dipping, which means that pre-galvanized barricades are less expensive to produce. Pre-galvanized barricades are also lighter in weight, which makes them easier to move around and transport.

Advantages of Hot-Dipped Barricades

While pre-galvanized barricades have their advantages, hot-dipped barricades are generally considered to be superior in terms of durability and longevity. The thicker layer of zinc coating on hot-dipped barricades provides better protection against rust and corrosion, which means that they will last longer and require less maintenance over time.

Hot-dipped barricades are typically made of thicker steel than the pre-galvanized type, which means that hot-dipped barricades are less likely to warp or bend under crowd pressure. The heavier gauge of hot-dipped barricades also makes them less likely to be damaged during transport and storage.

For more information about the full line of barricade products, please visit our Barricade category and explore the wide range of options available.

If you liked this post check out our most recent post Here

LEAVE A COMMENT